Sintered Metal Filter Passive Regenerated

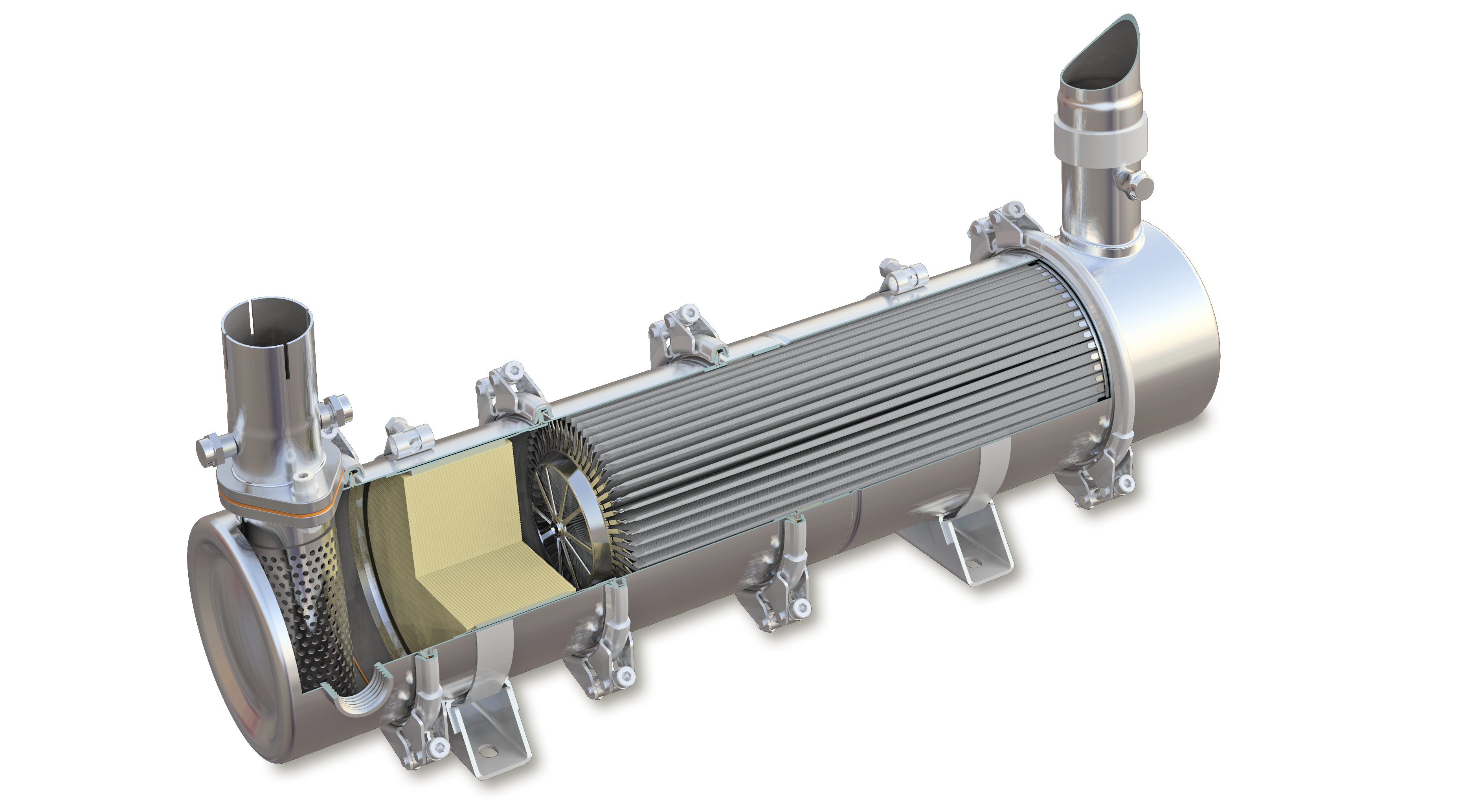

The modular SMF® technology was developed specially for applications in the medium to high range of performance. These filter systems can generally replace the original acoustic damper in the area of retrofitting and can be adapted individually to the machines and stationary applications.

Passively regenerated particle filter for individual requirements

The modular SMF® systems require no additional regeneration aids, additives or interventions in the engine management. Over the HJS service unit, the respective operating state and cleaning requirement of the filter system can be read off at any time.

Advantages

- Reduction of soot and the finest particles by more than 99%

- Flexible adaptation to different machines and engine powers

- The high ash compatibility ensures long driving performances.

- The catalytic coating enables an extended temperature window.

- The modular structure facilitates dismantling of the system in service.

Modularity

The system is structured in modular format in order to enable integration into the most varied applications with low expenditure. According to installed situation and range of performance, the customer can select from different system sizes and housing shapes within the framework of the extensive HJS delivery program.

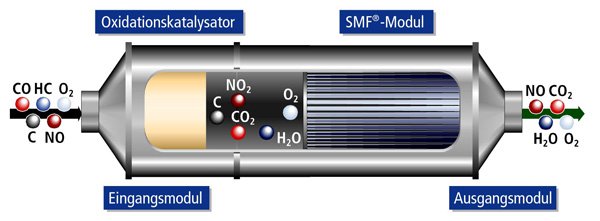

Technology and functioning

The hot engine exhaust gases with the soot particles are routed into the housing of the SMF®. The gaseous component parts of the exhaust gases flow through the microscopically fine pores of the filter bags. The soot particles are held back on the surface in this case, including the finest particles, and are deposited on the individual filter bags.

For the reduction of the soot gathered in the SMF®, the well-proven HJS-SMF® technology with passive regeneration is used. The HJS system combines a high-efficiency, upstream-connected diesel oxidation catalyzer (DOC) with an SMF®. As a result of an optimum system co-ordination, the filter is freed up continuously and effectively from the deposited soot.

The particle filter can be supplied with a catalytic coating for the support of regeneration.

Area of application

The SMF® CRT® system is also mainly suited for off-highway applications, for commercial vehicles and buses, as well as, in combination with a SCR system, for nitrogen oxide reduction. This technology is also used in stationary engines, railways or shipping,. HJS SCRT® systems are available both for application in the original equipment and for retrofit.

Go to HJS UK

Go to HJS UK