Our business in the UK is supported by our dedicated sales, project management and technical teams operating from our facility in Swindon, Wiltshire. From this facility, our engineering team provide nationwide installation and technical support.

The reduction of Nitrogen Oxides (NOx) contributing to air pollution is one of the most challenging public health issues facing the UK today. Diesel exhaust emissions have been classified as carcinogenic to humans, reassigning it to the same class of hazardous materials as asbestos, arsenic and mustard gas. The majority of urban areas in the UK are struggling to meet stringent European requirements for NOx emissions and the government has been ordered by the Supreme Court to take action in the quickest time possible.

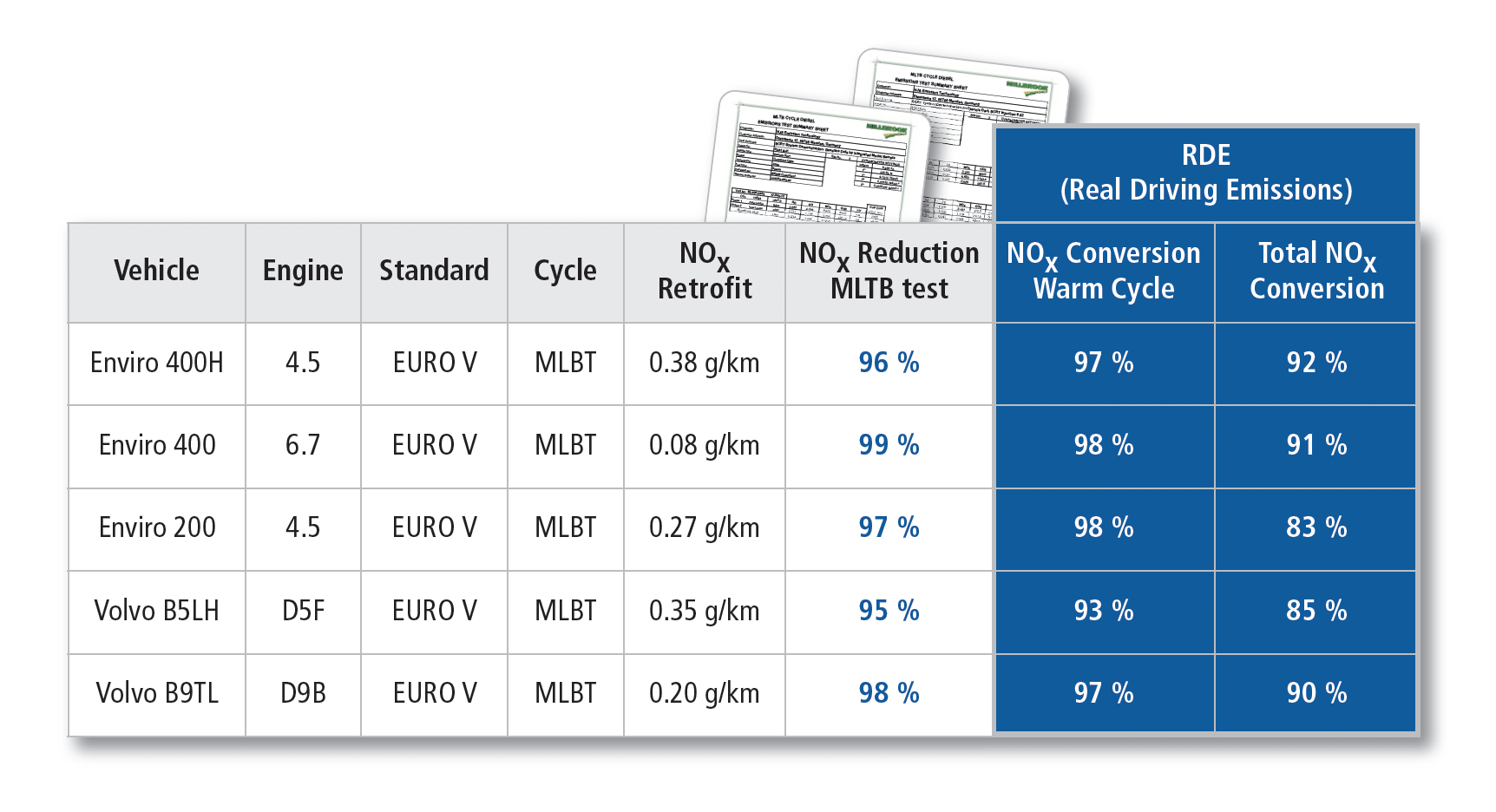

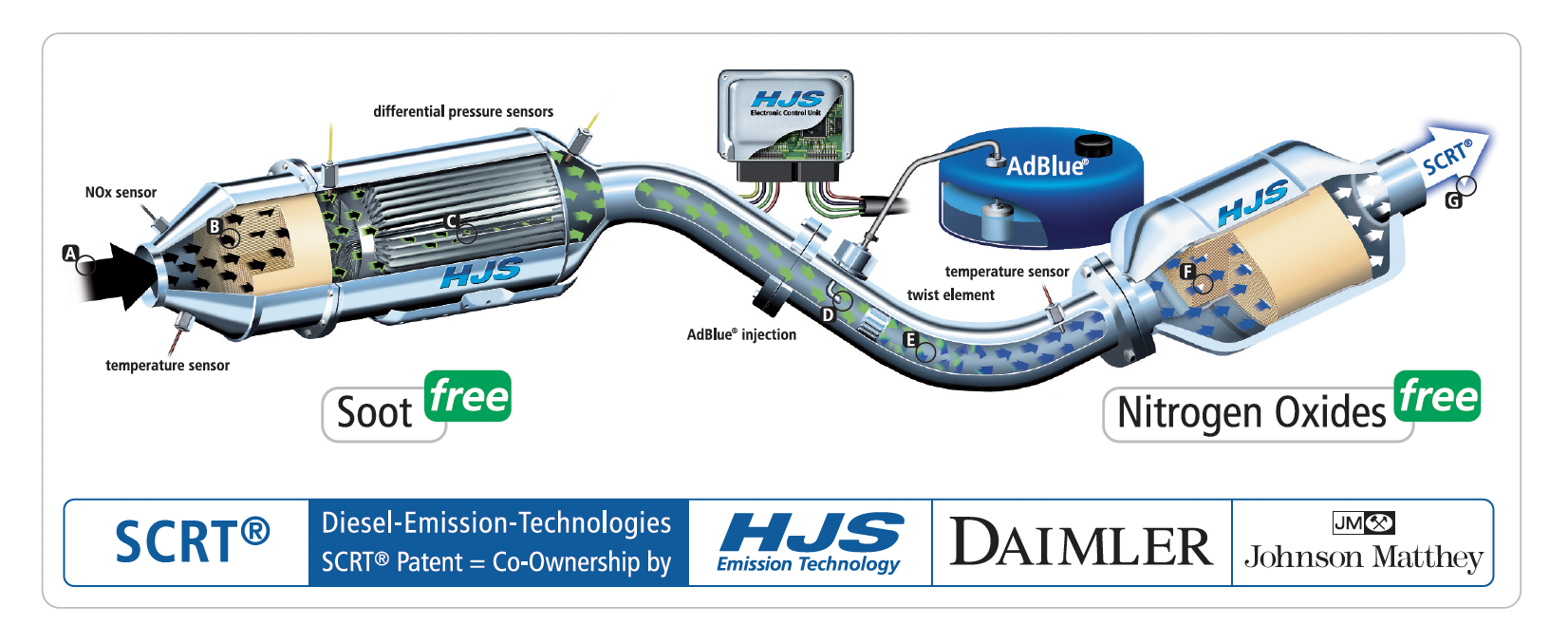

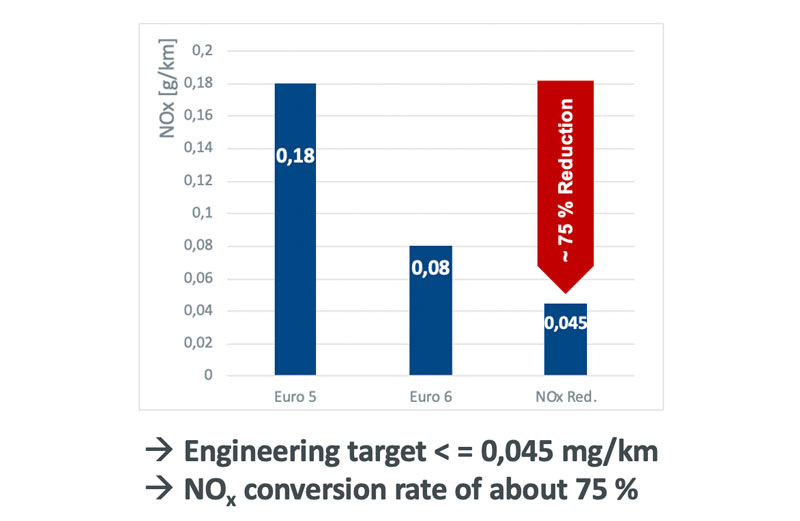

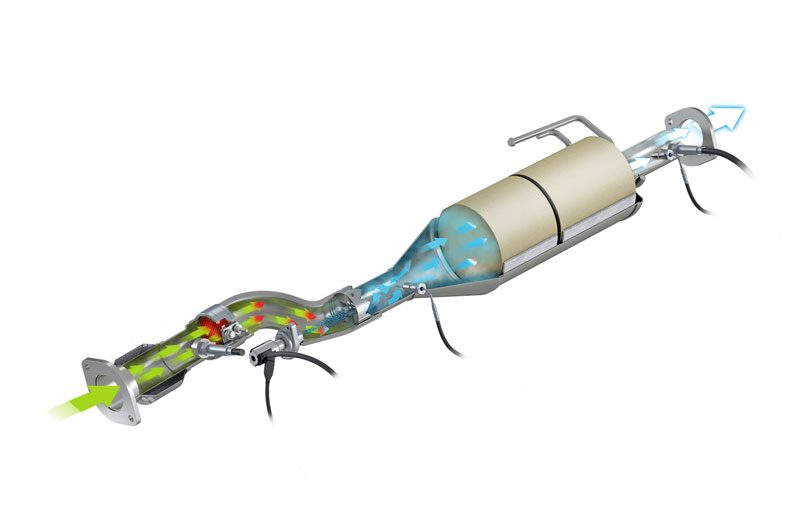

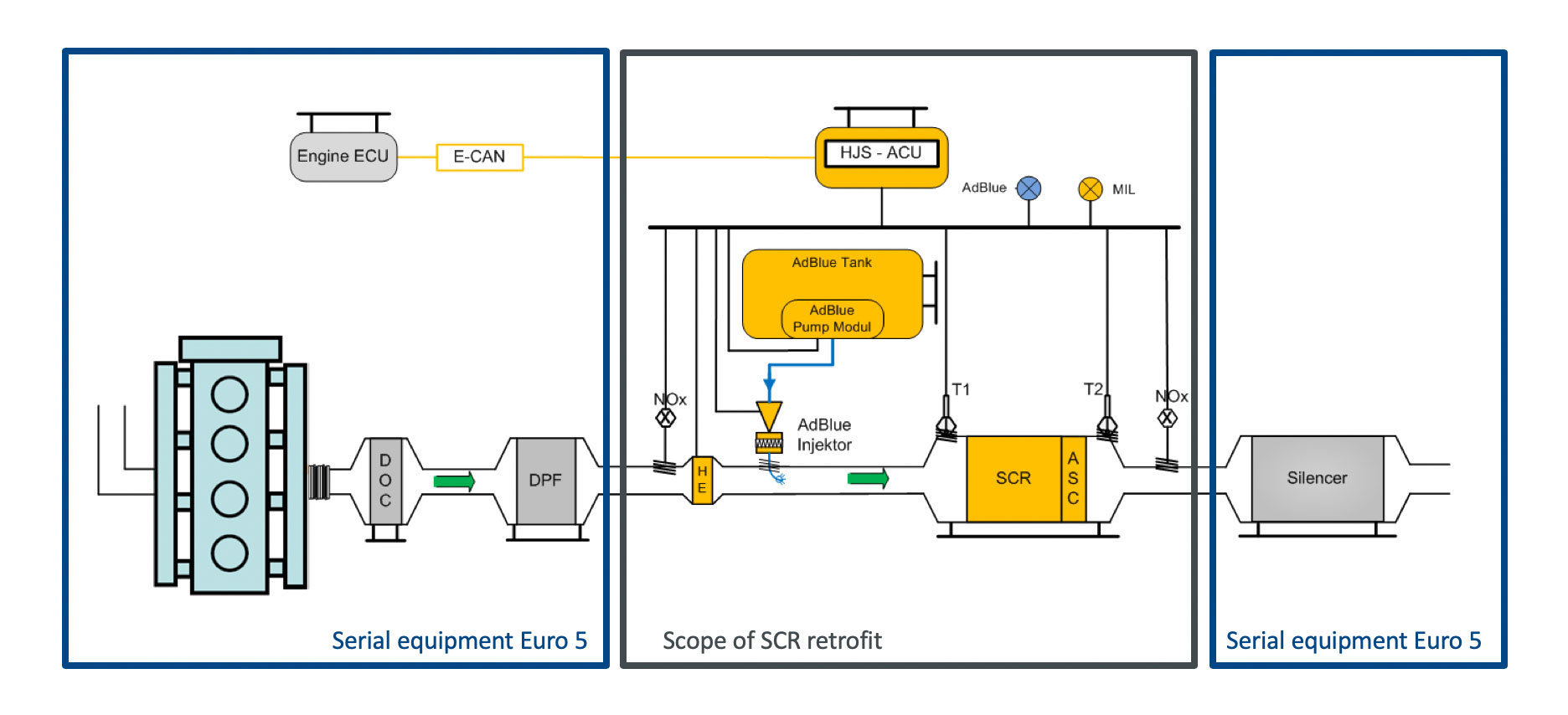

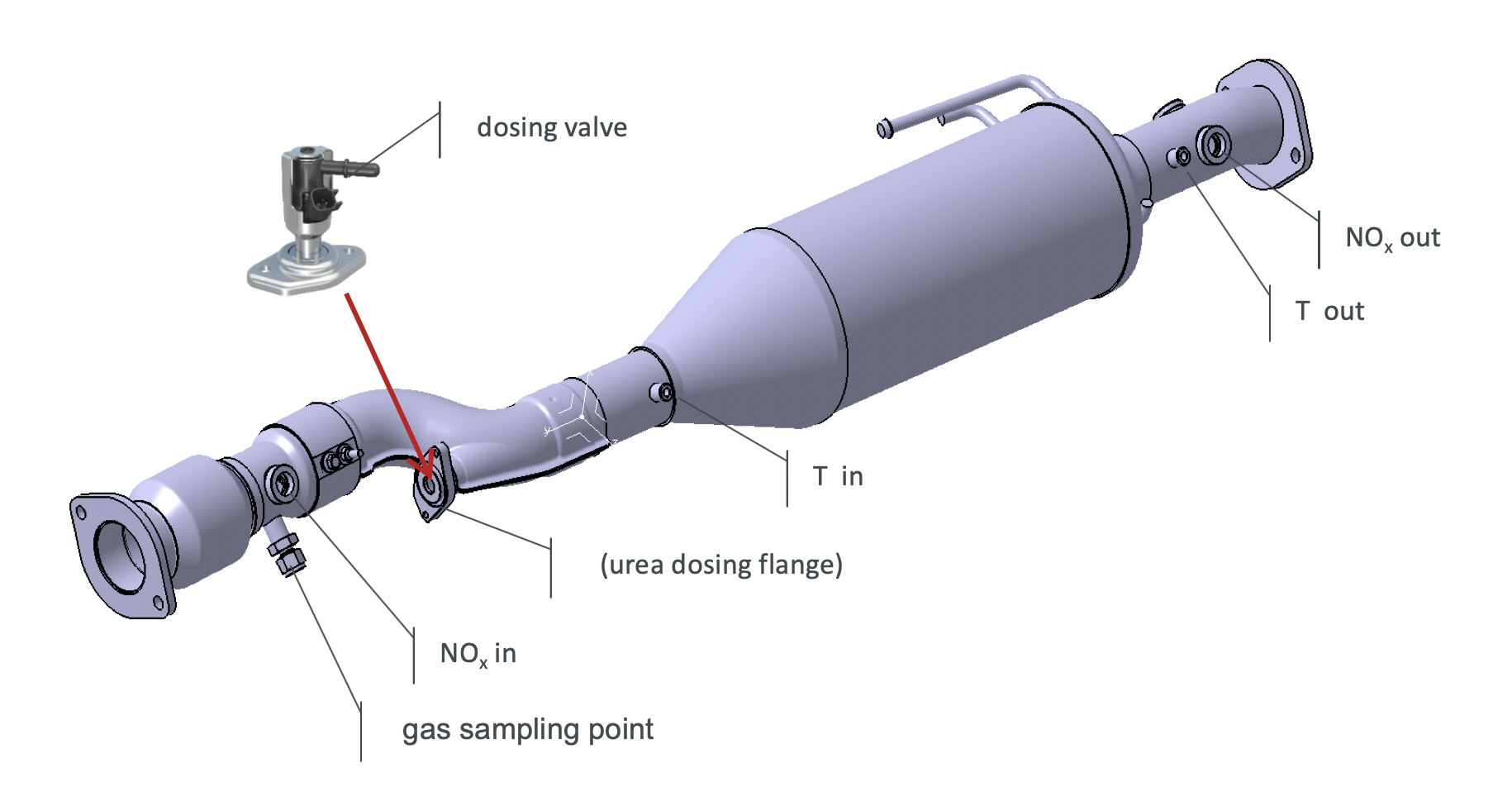

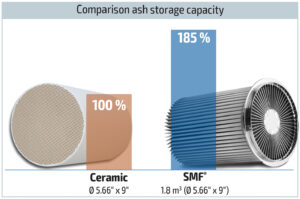

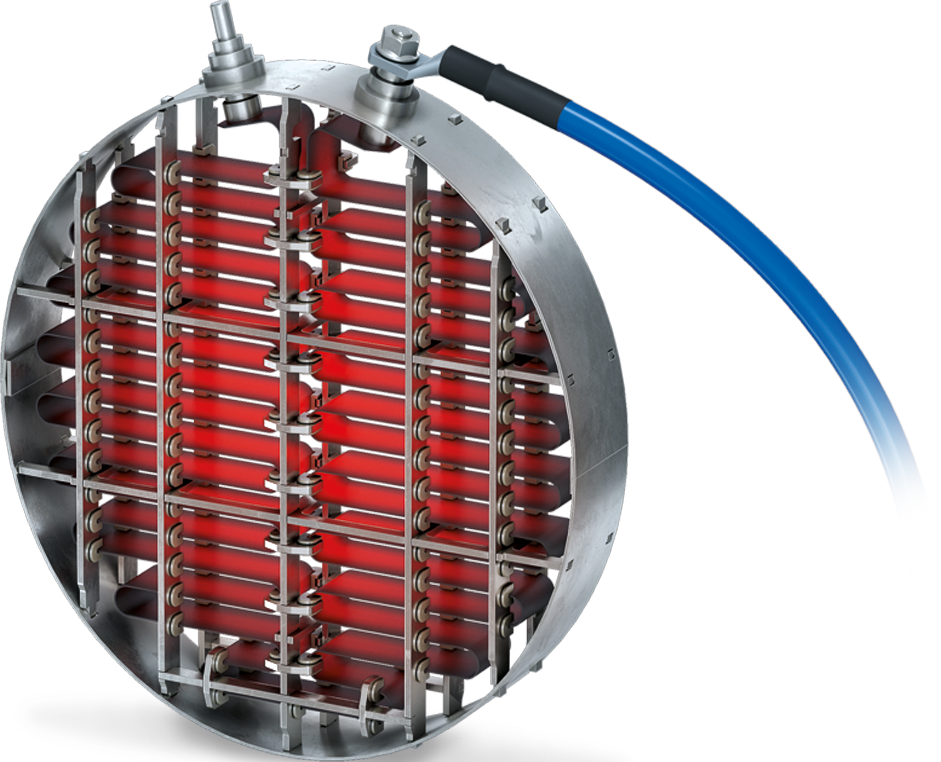

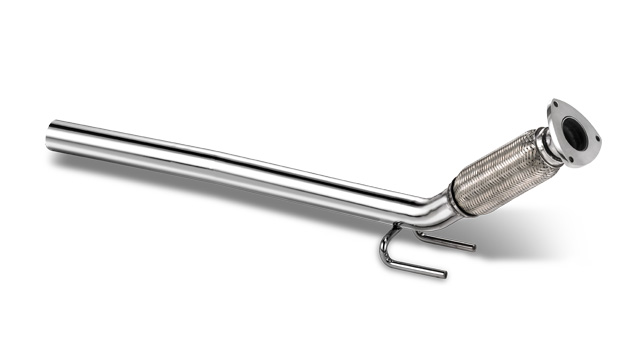

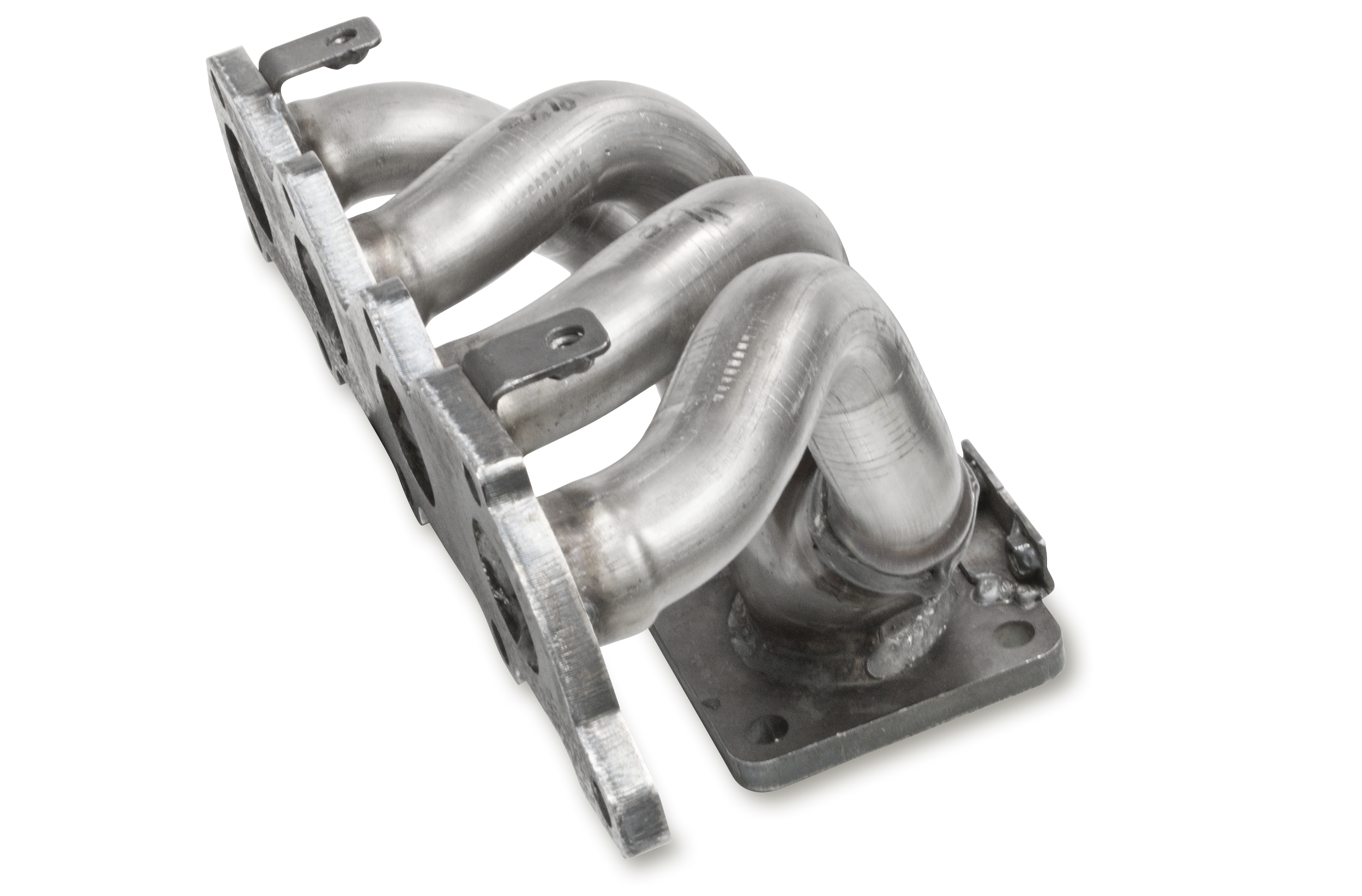

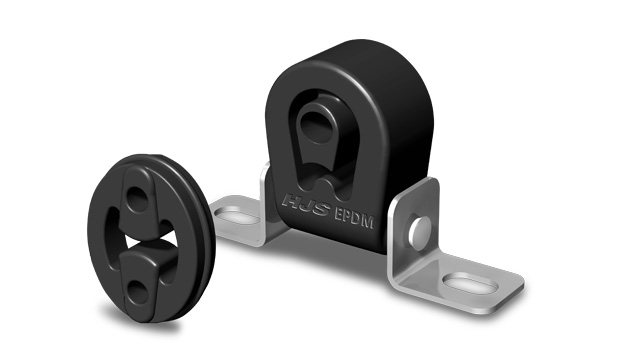

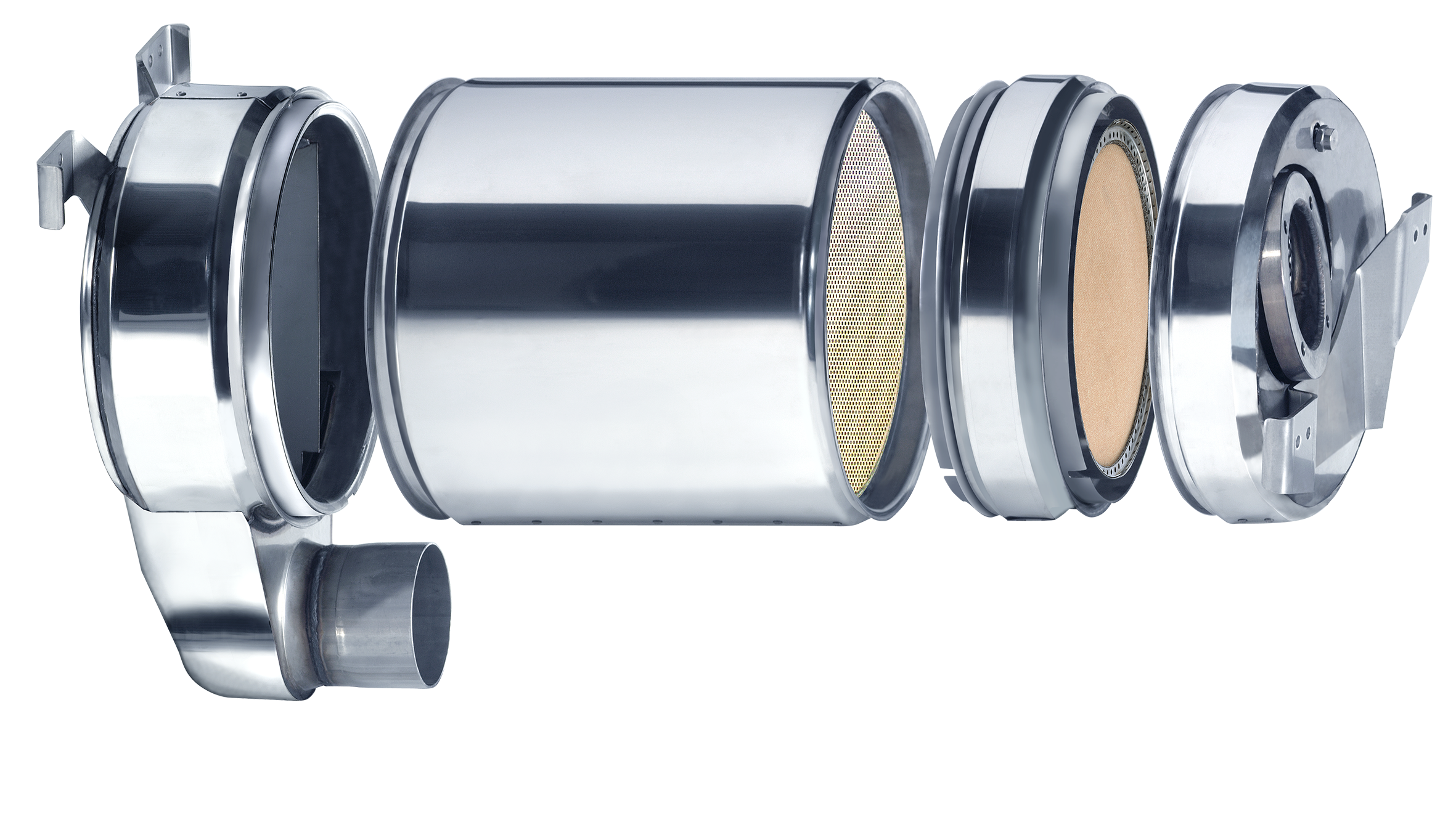

HJS work together with bus/coach operators and local authorities to improve air quality across the country. HJS are the pioneers of Selective Catalytic Reduction Technology (SCRT®) which can be retrofitted to significantly reduce NOx emissions and also virtually eliminate particulate matter. The HJS Real Blue SCRT® system meets Euro VI standards and is both ULEZ and CAZ compliant. System performance has been certified at Millbrook Proving Ground which has been followed up by several months of successful in service testing.

In 2019, Transport for London will introduce a 24/7 Ultra Low Emission Zone (ULEZ) to improve the problem of urban air quality in the capital. In addition to this Birmingham, Nottingham, Derby, Southampton and Leeds will be introducing Clean Air Zones (CAZ’s). 28 more cities and towns have also been identified requiring additional measures and Glasgow will become Scotland’s first Low Emission Zone at the end of 2018.

The HJS Real Blue SCRT® system is accredited by the Energy Saving Trust’s CVRAS (Clean Vehicle Reduction Technology Scheme). Our approved technology allows vehicles to be upgraded to meet LEZ, ULEZ and CAZ requirements and complies with the conditions set out within the Clean Bus Technology Fund (CBTF).

Go to HJS UK

Go to HJS UK